Legionella management is a critical operational responsibility for businesses operating large or complex hot water installations. In Rivervale, facilities such as hotels, gyms, apartment complexes, and commercial buildings rely on centralised systems that can create conditions where Legionella bacteria may proliferate if not properly controlled. Understanding temperature management and regulatory testing obligations is essential for reducing health risks, maintaining compliance, and protecting occupants.

This article explains how Legionella develops in large systems, why temperature control is the primary defence, and what testing and oversight responsibilities businesses must meet when managing Hot Water Systems Rivervale.

Understanding Legionella Risk in Commercial Hot Water Systems

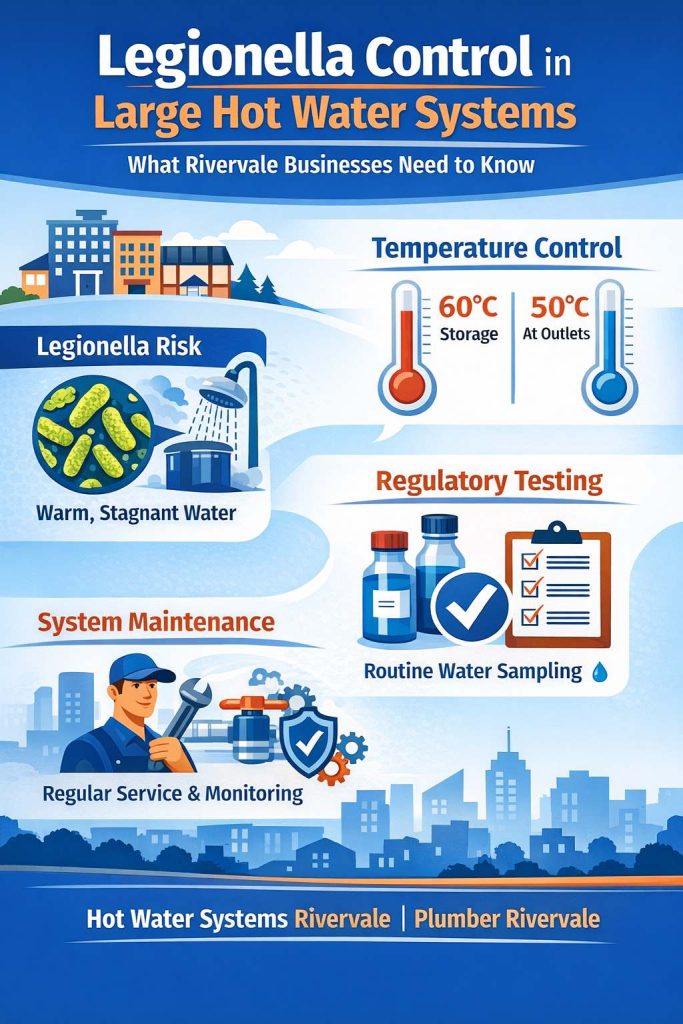

Legionella bacteria thrive in warm, stagnant water, typically between 20°C and 45°C. Large-scale hot water systems are particularly vulnerable due to extended pipe runs, storage tanks, dead legs, and periods of low water usage. Without consistent temperature control and monitoring, bacteria can multiply and spread through aerosols released from showers, taps, and cooling systems.

In business environments, exposure risks are higher because systems serve multiple users daily. An outbreak can result in serious illness, operational shutdowns, regulatory investigation, and reputational damage. As a result, Legionella prevention is not simply a maintenance issue—it is a core part of building risk management.

Temperature Maintenance: The Primary Control Measure

Maintaining correct water temperatures is the most effective method for controlling Legionella growth in large hot water systems. Regulatory guidance consistently emphasises temperature control as the first and most reliable safeguard.

For storage-based systems, hot water must be stored at a minimum of 60°C. This temperature inhibits bacterial growth within tanks and calorifiers. At outlets such as taps and showers, hot water should reach at least 50°C within one minute of operation. In healthcare or aged care environments, thermostatic mixing valves may be used to reduce scalding risk while still maintaining high temperatures upstream.

Circulation systems must also be balanced to ensure heat is maintained across the entire pipe network. Poor circulation can create cooler zones where bacteria can survive. Regular verification of flow temperatures at multiple outlets is essential to confirm the system performs as designed.

Temperature records should be documented and retained as evidence of ongoing control. This documentation forms a key part of compliance audits and risk assessments.

Regulatory Testing and Monitoring Obligations

While temperature control is fundamental, it must be supported by routine testing and inspection. Businesses managing large systems have a duty to demonstrate that Legionella risks are being actively managed rather than assumed.

Regulatory testing typically involves periodic water sampling from representative points within the system. These samples are analysed by accredited laboratories to detect Legionella presence and concentration levels. Testing frequency depends on building type, system complexity, and risk profile, with higher-risk environments requiring more frequent sampling.

In addition to microbiological testing, inspections should assess system condition, including pipework integrity, storage tank cleanliness, valve performance, and evidence of stagnation. Identified issues must be addressed promptly, with corrective actions recorded.

Engaging a qualified plumber, Rivervale ensures that sampling points are correctly selected, temperatures are accurately measured, and any required system adjustments are carried out in accordance with standards.

Responsibilities for Business Owners and Facility Managers

Legionella control is ultimately the responsibility of the person or entity in control of the premises. This includes business owners, strata managers, and facility operators. Delegating maintenance tasks does not remove accountability; it requires ensuring that competent professionals are engaged and that monitoring programs are maintained.

A structured Legionella management plan should outline temperature targets, inspection schedules, testing intervals, and response procedures if results exceed acceptable limits. This plan should be reviewed regularly, particularly following system modifications or changes in building use.

Working with an experienced plumber supports compliance by ensuring systems are designed, maintained, and adjusted with Legionella prevention in mind rather than reactive fault repair alone.

System Design and Ongoing Risk Reduction

Beyond routine maintenance, system design plays a major role in long-term Legionella control. Minimising dead legs, ensuring adequate insulation, maintaining correct pipe sizing, and upgrading outdated components all contribute to more stable temperatures and reduced bacterial risk.

For existing buildings, periodic system reviews can identify design weaknesses that increase exposure. Targeted upgrades may significantly improve safety while also enhancing energy efficiency and system reliability.

Businesses operating Hot Water Systems in Rivervale benefit from proactive oversight that treats Legionella prevention as an ongoing operational priority rather than a compliance checkbox.

Conclusion

Legionella control in large hot water systems requires consistent temperature management, structured testing, and clear accountability. Businesses in Rivervale must understand how system design, maintenance practices, and regulatory monitoring intersect to protect occupants and meet legal obligations.

By maintaining correct temperatures, documenting performance, and responding promptly to test results, organisations reduce health risks while demonstrating due diligence. A well-managed hot water system is not only safer but also more reliable, supporting uninterrupted operations and long-term asset performance.