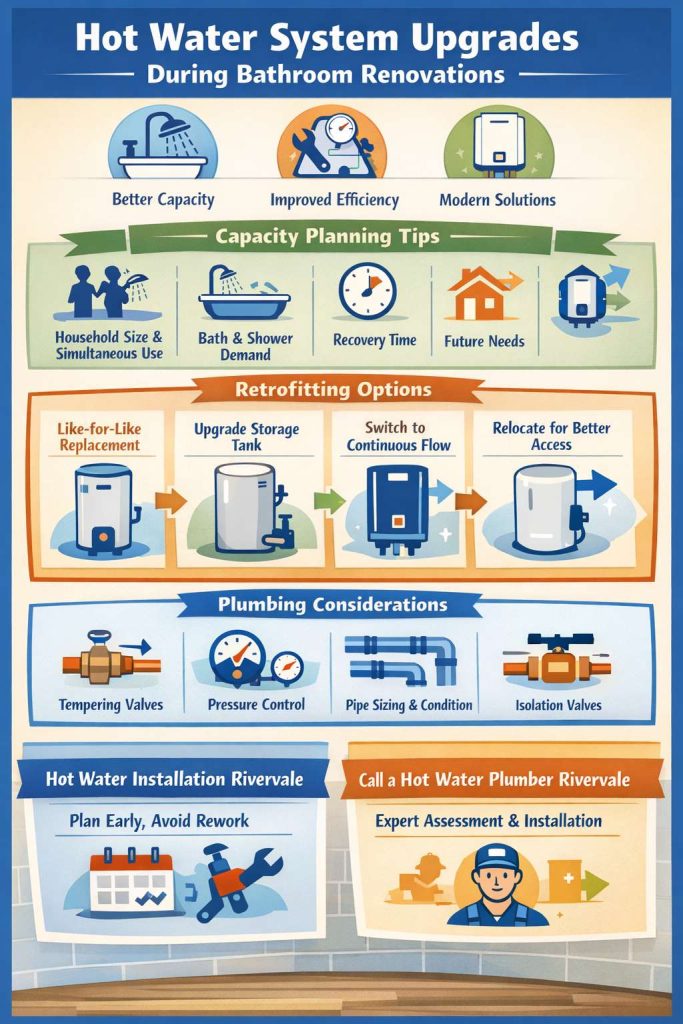

Bathroom renovations create a practical window to upgrade a hot water system without reopening walls, disturbing new tiling, or reworking finished plumbing. When we align the hot water upgrade with the renovation scope, we can reduce rework, improve daily performance, and ensure the system matches the household’s real demand profile—rather than relying on what was installed years ago.

Why renovations are the best time to upgrade hot water

A bathroom renovation typically involves changes to fixtures, pipework access, and sometimes layout. That access makes it easier to address common upgrade triggers, including:

- Inconsistent temperature during showers

- Slow recovery after consecutive uses

- A tank that is undersized for current occupancy

- A unit approaching end-of-life, with higher running costs or reliability risk

- Renovation changes such as a rain shower, larger bath, or additional bathroom use patterns

Upgrading during the renovation phase also supports cleaner compliance outcomes (valves, tempering requirements, clearances, and safe isolation) because the works are already being assessed as part of the broader plumbing scope.

Capacity planning that matches real-world use

Capacity planning is the difference between a system that “works on paper” and a system that supports real morning routines. The right sizing starts with demand, not just the number of bathrooms.

Key demand drivers to consider:

- Household size & simultaneous use: Two showers running at once changes the demand curve immediately.

- Fixture flow rates: Water-efficient heads reduce demand, while rain showers and high-flow tapware increase it.

- Bath usage: A full-sized bath can be a major single draw.

- Recovery expectations: How quickly the system needs to deliver the next round of hot water after peak use.

- Future-proofing: Planned occupancy changes, teenagers growing up, or adding a second bathroom later.

A renovation is also the right time to check whether existing pipe sizing, pressure control, and isolation points still suit the intended usage. This planning approach avoids the common outcome of fitting a new unit while leaving legacy constraints untouched.

Retrofitting options during bathroom renovations

Retrofit selection should balance space, supply type, upgrade complexity, and performance expectations. The most suitable option depends on what is already in place and what the renovation is changing.

Like-for-like replacement (lowest disruption)

If the current location and service connections suit the new design, replacing the existing unit with a modern equivalent can be the most efficient pathway. This approach can minimise changes to pipe runs, penetrations, and mounting points—useful where access is limited or the renovation scope is tight.

Upgrading storage capacity

Where the existing storage unit is undersized or slow to recover, a capacity increase can stabilise temperature and reduce outages during peak use. The key is ensuring the installation space, support, and safety components are suitable, particularly where cupboards, alcoves, or external mounting locations are being altered.

Converting to continuous-flow

A continuous-flow system can suit households that prioritise on-demand hot water and have the right gas supply conditions and venting options. During a bathroom renovation, we can often route services more cleanly, position units more effectively, and integrate isolation and tempering in a way that fits the new layout.

Relocating the system for better performance

Renovations sometimes shift bathroom layouts, and this can expose inefficiencies such as long pipe runs and delayed hot water delivery. Relocation can reduce lag time and improve convenience, but it requires careful planning for mounting, ventilation, safe access, and compliant discharge routing. If relocation is being considered, it should be decided early—before cabinetry and waterproofing are finalised.

Plumbing considerations that impact the result

Hot water upgrades don’t exist in isolation. Renovation changes can affect the system’s performance and compliance, so it is worth addressing related items while walls and floors are open:

- Tempering requirements to control delivery temperature to bathroom outlets

- Isolation valves for safe servicing without shutting down the whole property

- Pressure control where required to protect fixtures and the hot water unit

- Pipe condition & sizing, especially if old lines restrict flow or contribute to temperature instability

- Placement & access for future servicing, including safe clearance and working space

These details influence reliability, safety, and how well the system supports the renovated bathroom long-term.

A renovation-aligned upgrade plan

To keep the renovation moving and avoid last-minute compromises, the hot water decision should be made before final fixture selection and before waterproofing begins. That timing allows us to align pipework routes, valve placement, and unit selection to the finished design rather than forcing a retrofit after surfaces are completed.

For properties in Rivervale, we regularly coordinate Hot water installation Rivervale with bathroom renovation timelines, so the upgrade integrates cleanly with new plumbing points, tapware, and layout changes. With the right planning, a Hot water system installation becomes a value add to the renovation rather than an extra complication.

When to bring in a Rivervale hot water specialist

If the renovation includes high-demand fixtures, multiple users, or any hot water reliability issues already exist, professional assessment helps prevent undersizing and avoidable rework. We typically recommend involving a hot water Plumber Rivervale early—before fixture rough-in—so the upgrade supports the design and daily usage. A qualified hot water Plumber in Rivervale can also confirm whether the current services, location, and safety components are fit for purpose, and recommend a retrofit pathway that aligns with compliance requirements and practical household needs.

Summary

Hot water upgrades during bathroom renovations are most successful when capacity planning is done upfront and retrofit choices are aligned to the new layout, fixture demand, and long-term usage. By leveraging renovation access, we can reduce rework, improve performance, and deliver a system that supports daily routines with fewer temperature fluctuations, faster recovery, and better serviceability.