Hot water systems are long-term capital assets within residential & commercial properties. While tanks, valves & thermostats receive attention during servicing, the anode rod remains one of the most critical yet overlooked components. Its primary function is corrosion control, directly influencing tank longevity, water quality & lifecycle cost management.

Understanding how anode rods operate, when they require replacement & how maintenance scheduling protects the cylinder structure is essential for property owners seeking predictable performance and reduced replacement expenditure.

What an Anode Rod Does

An anode rod is a sacrificial metal core, typically magnesium, aluminium or zinc-coated alloy, installed inside the storage tank. Its purpose is to attract corrosive elements present in heated water before they attack the steel tank lining.

Water naturally contains dissolved minerals, oxygen & salts. When heated, these elements accelerate electrochemical reactions. Without protection, the steel tank wall begins to corrode from the inside. The anode rod sacrifices itself by corroding first, thereby preserving the tank structure.

This process is known as cathodic protection. It slows internal rust formation and delays tank failure.

Why Corrosion Is the Primary Threat

Most storage hot water units fail due to internal corrosion rather than mechanical malfunction. Even tanks with glass-lined interiors are vulnerable once microscopic cracks appear in the lining.

Corrosion risks increase when:

- Water hardness is high

- Chloride levels are elevated

- Water temperature settings are excessive

- Maintenance intervals are extended

For households relying on a Hot water system Rivervale, local water chemistry plays a direct role in how quickly an anode depletes. Ignoring inspection schedules shortens tank lifespan significantly.

Lifespan Impact of a Functional Anode

A properly maintained anode rod can extend tank life by several years. In many cases, premature tank replacement occurs simply because the anode was never inspected or replaced.

Typical service benchmarks:

- Inspection every 2–3 years

- Replacement when 50% or more of the rod has deteriorated

- Earlier review in high-mineral water zones

Once the rod is fully consumed, corrosion begins attacking the tank walls immediately. At that stage, structural deterioration accelerates and replacement becomes inevitable.

A qualified Hot water Plumber Rivervale will assess both rod condition & tank integrity during scheduled servicing.

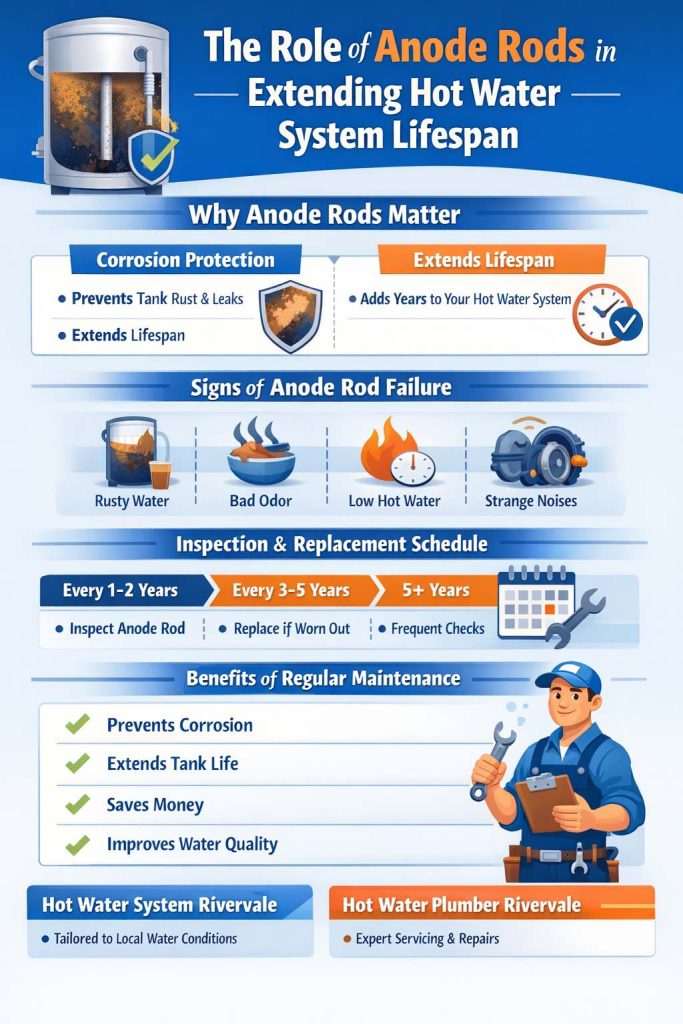

Signs an Anode Rod May Be Failing

While the anode itself is internal and not visible externally, indirect indicators may appear:

- Rust-coloured water

- Metallic odour

- Reduced hot water clarity

- Popping or rumbling noises from sediment build-up

- Visible corrosion around tank fittings

These symptoms often indicate that internal protection has diminished.

Maintenance Scheduling & Risk Mitigation

Preventative servicing is significantly more cost-effective than emergency tank replacement. Maintenance planning should align with manufacturer guidelines, water quality factors & system age.

Recommended schedule structure:

Year 1–2: Baseline inspection & system performance check

Year 3: Anode inspection & sediment assessment

Year 5+: Increased inspection frequency as depletion rates accelerate

For properties operating a Hot water system Rivervale, documented servicing ensures compliance with warranty terms and reduces unexpected downtime.

Engaging a Hot water Plumber Rivervale for scheduled inspection provides measurable benefits:

- Reduced corrosion exposure

- Extended tank life

- Lower lifecycle cost

- Maintained water quality

- Preserved manufacturer warranty

Material Selection Considerations

Different anode materials suit different water conditions:

- Magnesium rods: Higher protection output but faster depletion

- Aluminium rods: Longer lifespan in hard water areas

- Zinc-enhanced rods: Useful where odour control is required

Selection should be based on local water analysis rather than default installation.

The Cost of Neglect

Once internal rust perforates the tank, leaks occur without warning. At that point, repair is not viable; full replacement is required. This involves equipment cost, labour, potential property damage & operational disruption.

By contrast, an anode replacement is a controlled, scheduled service procedure with predictable cost.

Strategic Asset Protection

Hot water systems represent essential infrastructure within any property. Anode rod inspection is not optional maintenance; it is a corrosion management strategy.

By implementing structured servicing intervals, monitoring depletion rates & engaging qualified technical support, property owners can maximise return on installation investment and avoid premature system failure.

Corrosion is inevitable. Tank failure is not.